3M Flexographic Plate Mounting Tapes

3M Cushion-Mount Plus Plate Mounting Tape with Easy Mount Adhesive High Plateside Adhesion E1015H

The 3M Cushion-Mount Plus Plate Mounting Tape with Easy Mount Adhesive High Plateside Adhesion E1015H is a high-performance foam mounting tape designed for mounting flexographic print plates to cylinders or sleeves. This tape provides excellent print quality for process, combination, and solid printing.

Engineered for Narrow Web Applications and CI Flexographic Printing Presses

Precision Meets Performance — Only with 3M™

Balance Your Print. Balance Your Output.

Color-Coded. Performance-Tested. Operator-Approved.

Benefits

Excellent Print Quality

Provides excellent print quality for process, combination, and solid printing.

3M Comply Adhesive System

Air-release channels for bubble-free, fast, and accurate mounting.

Exceptional Cushioning

Reduces press vibration for cleaner, sharper prints.

Improved Productivity

Reduces downtime and improves productivity with easy application and clean removability.

Increased Efficiency

Allows for consistent caliper control and the use of multiple foam densities on a print job to optimize print quality.

Reduced Waste

Minimizes waste with clean plate removal and easy removability.

Product Features

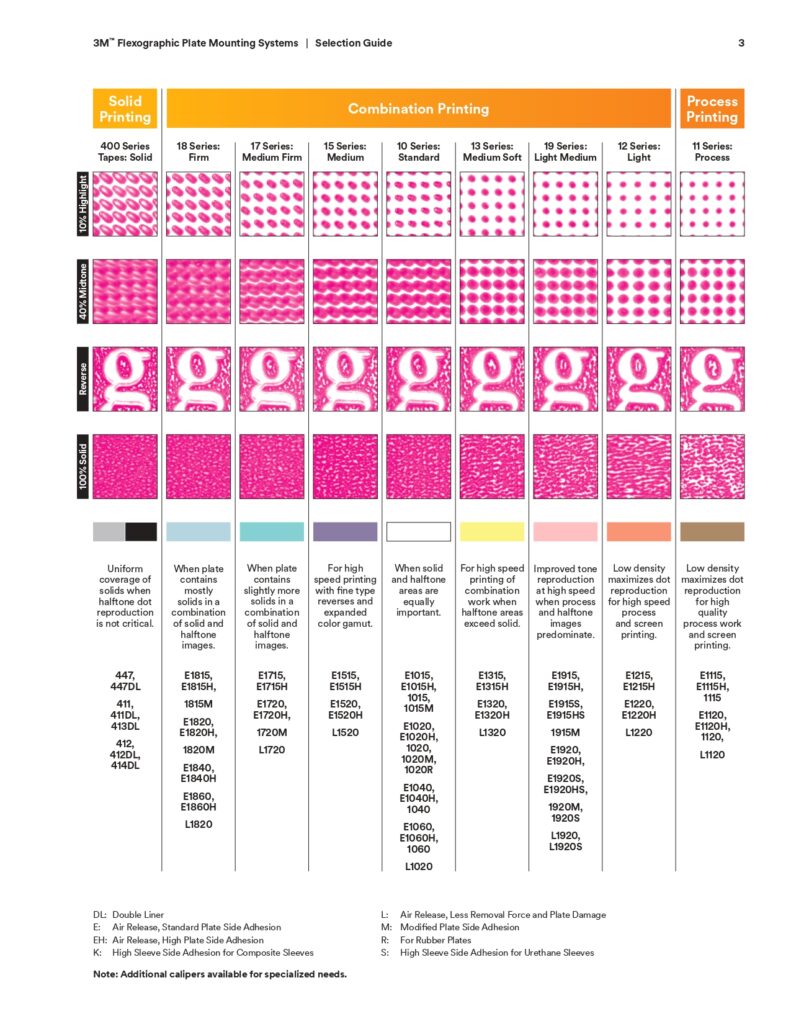

Complete Range of Foam Densities

Offers a comprehensive range of foam densities to provide excellent print quality from process to combination to solid printing.

Consistent Caliper Control

Allows for consistent caliper control, enabling printers to use multiple foam densities on a print job to optimize print quality.

Easy Mount Liner

Features the 3M proprietary Easy Mount liner, creating micro-channels in both adhesive surfaces for easy application and clean removability.

High Plateside Adhesion

Offers excellent holding power on-press with high plateside adhesion and clean plate removal when demounting.

Easy Application and Removability

Provides easy application at mounting and clean removability when demounting, reducing downtime and improving productivity.

Engineered Layer Structure

A high-performance combination of liner, adhesive, reinforced film, and closed-cell PE foam.

Storage and Shelf Life: Store under normal conditions of 60° to 80°F (16° to 27°C) and 40 to 60% relative humidity in the original carton. To obtain best performance, use within two years from date of manufacture.

E1015H Technical Information Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Typical Physical Properties

| Property | Values | |

| Tape Thickness | 0.432 mm | 17 mil |

| Application Thickness | 0.381 mm | 15 mil |

| Film Thickness | 0.114 mm | 4.5 mil |

| Lot to Lot Tolerance | ± 0.038 mm | ± 1.5 mil |

| Typical Application Area Caliper Variation | ± 0.01 mm | ± 0.4 mil |

| Adhesive | Differential Acrylate | |

| Adhesive Carrier | Standard White Foam | |

| Density | 450 kg/m³ | 28 lb/ft³ |

| Type of Printing | Combination of solid and line with tone reproduction where solids and process are equally important | |

| Compression Deflection: 10% Compression | 104 kPa | 15 lb/in² |

| Compression Deflection: 25% Compression | 207 kPa | 30 lb/in² |

Typical Cured Characteristics

Shore A Hardness: 65

Available Sizes:

| Property | Values | Values |

| Standard Roll Length | 32.9 m | 36 Yards |

| Minimum Available Width | 50.8 mm | 2 inch |

| Maximum Available Width | 1371.6 mm | 54 inch |

| Normal Slitting Tolerance | ± 0.794 mm | ± 1/32 inch |